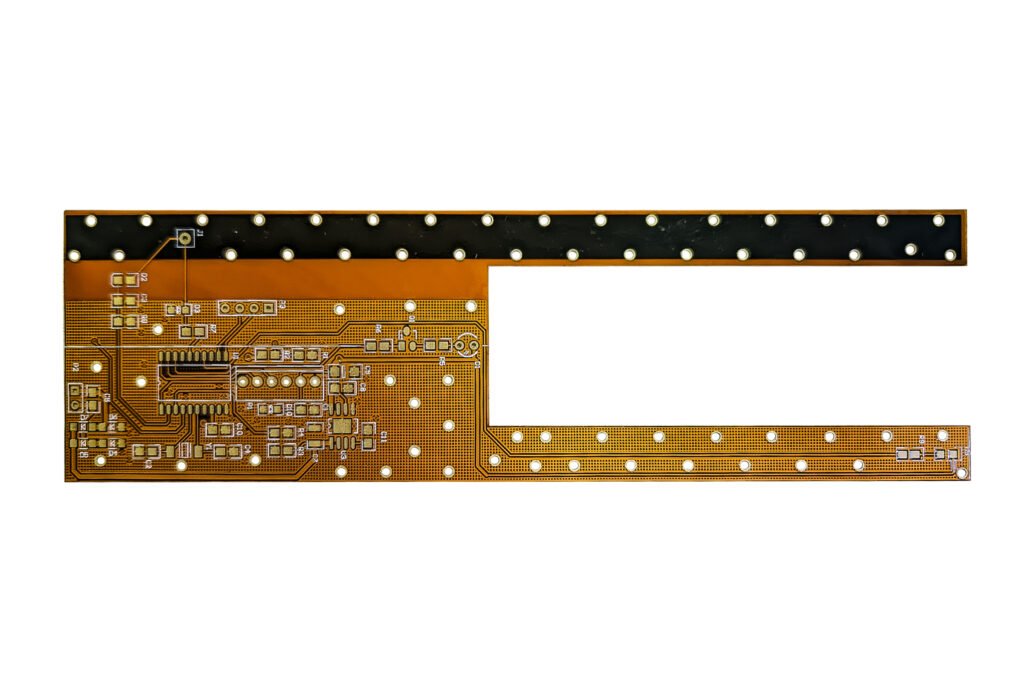

In the world of electronics, the printed circuit board (PCB) is the foundation upon which all components are assembled and interconnected. Beyond the intricate network of electrical traces and components, there’s a key element often overlooked-Characters. These are essential for identifying components, providing important manufacturing details, and ensuring easy assembly and future maintenance. Designing the character size parameters on a PCB requires careful consideration of legibility, manufacturing capabilities, and spacing to ensure that text serves its purpose efficiently. In this essay, we will explore how to design character size parameters on a PCB, incorporating both traditional practices and modern improvements.

If you have no idea of the Characters (silkscreen printing), please visit my last post “What is PCB Silkscreen Printing?”.

Why it is Importance of Text on a PCB?

PCB text is crucial for various purposes:

- Component Labels: Helps technicians identify and assemble components correctly.

- Manufacturing Information: Details like the manufacturer, production date, or batch number ensure traceability.

- Debugging and Maintenance: Text such as pin labels, instructions, or warnings helps engineers during the debugging or repair process.

- Branding and Compliance: Logos and certification marks ensure product authenticity and regulatory compliance.

However, designing characters on a PCB isn’t just about aesthetics. It involves striking a balance between legibility and manufacturing constraints, while also avoiding interference with functional areas of the board.

Do You Have Idea of Traditional Silk-Screening Method?

In the past time, silk-screening has been the most common method for applying text to a PCB. This process involves using a mesh screen to apply ink onto the board’s surface. The resulting text, referred to as silk-screen characters, can vary in size and quality, depending on the design and manufacturing requirements. While traditional silk-screening remains prevalent, more advanced methods such as high-definition and high-precision characters are now available, offering customers flexibility in terms of clarity and resolution.

- Standard Silk-Screen Characters: These are produced using traditional screen printing and are sufficient for most PCB applications.

- High-Definition and High-Precision Characters: These offer smaller stroke widths and tighter tolerances, making them ideal for more compact or high-density PCB designs.

What are the Character Size Parameters for Different Fonts?

When designing characters, the key parameters are stroke width (the thickness of character lines) and character height. Ensuring these are within manufacturing tolerances is critical to avoiding issues like smudging or illegibility after production.

1 Standard Font

- Character Stroke Width: ≥ 0.15 mm

- Character Height: ≥ 1 mm

- High-Precision Font: For high-precision applications, a stroke width as small as 0.1 mm and a height of 0.8 mm may be acceptable.

2 Hollow Font

- Character Stroke Width: ≥ 0.2 mm

- Character Height: ≥ 1.5 mm

It’s important to maintain proportionate sizes between stroke width and character height. If the character line width is too thin relative to its height, the text may not be clearly visible after manufacturing processes like etching or solder masking.

Special Note: If the text dimensions fall below these minimum values, PCB manufacturers may not be able to adjust the character height in the design files, but they could adjust the stroke width to compensate. It’s essential to design within the manufacturer’s capabilities to avoid complaints about blurry or unclear text caused by limitations in production technology.

What are the spacing considerations for character design?

Character-to-Solder Pad Distance

One of the most critical aspects of text design on a PCB is ensuring that text doesn’t interfere with other functional elements, such as solder pads or traces. Characters overlapping solder pads can cause defects during assembly, particularly solder bridging during surface-mount technology (SMT) processes.

Minimum Spacing:

- Characters should be at least 0.15 mm away from solder pads.

- There should be at least 0.15 mm of spacing between character lines to prevent merging or smudging during silk screening or etching.

If the distance between the text and solder pads is less than 0.15 mm, the engineering team may remove the text to avoid any interference during assembly. If your design requires text in these areas, it’s crucial to communicate this in the ordering process to avoid unwanted modifications.

Special Note: Any missing characters caused by proximity issues with solder pads will not be addressed in post-production complaints, as these are preventable design issues. It is the designer’s responsibility to ensure proper spacing in the design phase.

How to deal with copper surface text?

If characters are placed directly over exposed copper, which may be tinned or gold-plated, those characters are typically removed during production. This is because exposed copper areas are critical for electrical connections, and any text here could interfere with the PCB’s functionality or cause assembly issues.

What about characters on the board?

On areas of the PCB where there is no copper (referred to as the substrate), characters are generally retained entirely, regardless of whether the area is inked or not. This ensures that text remains visible for assembly instructions, component identification, or other purposes without affecting the board’s electrical properties.

Any suggestions for special character design instructions

In some cases, text may need to be placed in functional areas such as solder pads or copper regions due to specific design requirements. When this happens, designers must follow these special instructions:

- Prioritize Functional Areas: If text overlaps with solder pads or copper regions, the text should be removed or adjusted to prevent interference with the board’s functionality.

- Special Orders: Customers with unique requirements for character placement (e.g., text on exposed copper) must provide specific instructions when placing an order. These should be clearly communicated to the engineering team to ensure the final product meets the customer’s expectations.

For instance, if text must overlap solder pads, a remark such as “allow characters XXX to overlap with the solder pad” should be included when submitting design files. If this information isn’t provided, the default process will result in the removal of characters overlapping pads or copper areas within a 0.15 mm tolerance. Attention to Detail: Miscommunication in the design process can lead to characters being altered or removed. It’s critical that PCB designers and customers coordinate to ensure all requirements are met before production begins. The final production draft must be reviewed to avoid errors and ensure that all necessary markings remain intact.

Some practices for designing character size parameters are shared.

To ensure optimal character design on a PCB, here are some best practices to follow:

- Follow Manufacturer Guidelines: Always adhere to the manufacturer’s minimum character height and stroke width specifications to prevent issues with legibility and production.

- Ensure Adequate Spacing: Maintain at least 0.15 mm spacing between text and other elements such as solder pads or traces to avoid interference.

- Use Appropriate Fonts: Stick to simple, sans-serif fonts like Arial or Helvetica for maximum clarity and compatibility with silk-screen or copper etching processes.

- Review the Final Design: Always review the production draft with the engineering team to confirm that all text is clear, well-placed, and legible.

- Communicate Special Requirements: If specific text must overlap functional areas, make this clear when submitting files, so the final product meets your needs.

When Designing character on a PCB requires attention to both technical details and manufacturing limitations. By understanding the different methods of applying text, such as silk-screening or high-precision characters, and following the correct spacing and font guidelines, you can ensure that all text remains legible and functional. Careful planning and communication with M2PCB’s engineers can prevent common issues such as text interference or removal, resulting in a well-marked PCB that is easy to assemble, maintain, and trace.