How do I choose a PCB color?

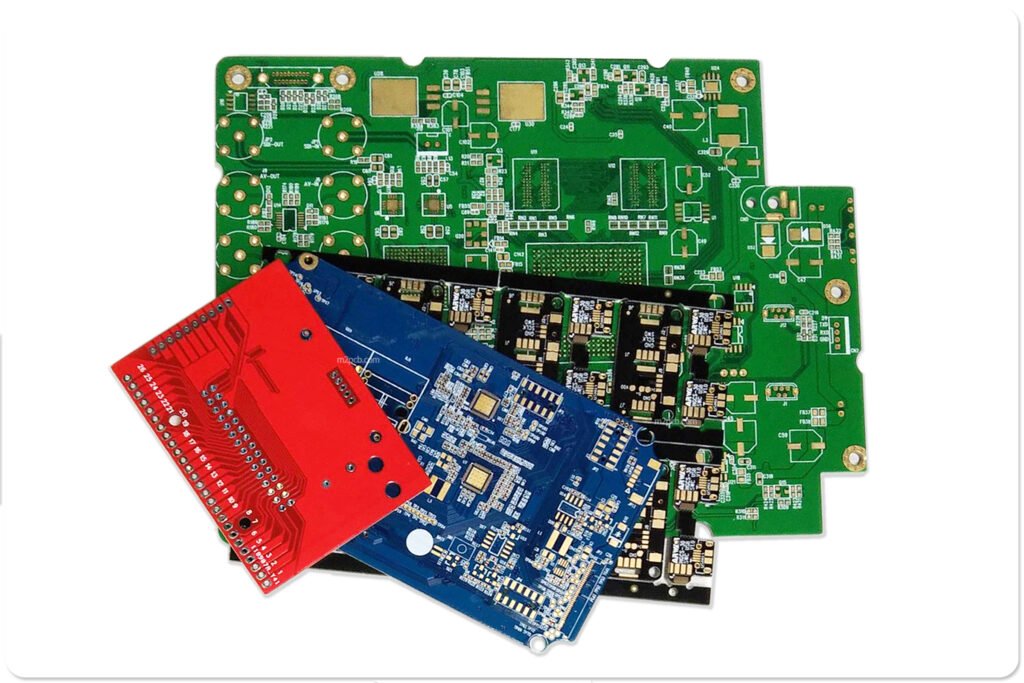

Choosing a PCB color mainly involves selecting the color of the solder mask.

Maybe you will ask: What’s the solder mask?

Which is the protective layer that covers the copper traces on the board. While the color itself doesn’t affect the performance of the PCB, it can have practical and aesthetic implications depending on your project’s needs. Here are some factors to consider when selecting a PCB color:

1. Aesthetic and Branding

- Brand Identity: If you’re working on a consumer product or a branded project, the PCB color can be chosen to align with your brand’s color scheme or visual identity.

- Professional Look: Some colors are considered more professional or premium-looking. Green is the industry standard, but colors like black or white can give the PCB a more sophisticated or modern appearance.

2. Ease of Inspection and Debugging

- Green (Standard): Green is the most common PCB color because it offers the best contrast for inspecting and troubleshooting boards. The green solder mask provides excellent visibility of traces, pads, and components. It’s also ideal for automatic optical inspection (AOI) in manufacturing, where machines visually inspect the board.

- Blue: Blue is another popular choice for PCBs and offers a good balance of aesthetics and trace visibility. It’s easy to work with and provides decent contrast when inspecting the board.

- Red: Red is often used for specific projects and offers moderate contrast. It’s an excellent option for visually distinct projects but may not be as easy to inspect as green or blue.

- Black: Black PCBs can look sleek and modern, but they have lower visibility for traces and components, making them harder to inspect and repair. They are also more prone to showing dust, scratches, and fingerprints.

- White: White PCBs are often used in LED lighting to reflect light better, but they offer the worst contrast for inspecting components and traces, making debugging more difficult.

3. Thermal Management

Black: Black absorbs more heat than lighter colors, so if heat dissipation is a concern, black may not be the best choice, especially in high-power applications like LED or industrial electronics.

White: White solder masks reflect light and heat, making them useful for applications where heat management is important, such as in LED lighting systems.

4. Cost and Availability

- Green: Since green is the most commonly used color, it is often the cheapest and most readily available option. Manufacturers generally have more experience with green, leading to better quality control and fewer defects.

- Other Colors (Blue, Red, Black, etc.): Non-standard colors like blue, red, and black may come at a slightly higher cost or longer lead times, depending on the manufacturer. However, this cost difference is often minimal unless you’re working on a very large production scale.

5. Special Applications

- Transparent Solder Mask: Some PCBs use a transparent or clear solder mask, which can be useful for decorative or artistic electronics where you want to showcase the copper traces or make the board look more visually appealing.

- Yellow/Purple/Other Colors: Rare colors like yellow, purple, or even orange can be chosen for special, unique projects, or to distinguish between different boards in complex systems.

What I Should to Consider When Choosing a PCB Color?

Functionality: If ease of inspection is crucial, stick with green, blue, or red for better contrast and visibility.

Aesthetics and Branding: If the PCB will be visible to users, you may prioritize colors that align with the brand or project aesthetics, such as black or white.

Thermal Management: In high-power or heat-sensitive applications, avoid dark colors like black that absorb more heat.

Cost and Availability: For mass production or cost-sensitive projects, green is usually the most economical and readily available choice.

Ultimately, the color choice is a balance between aesthetics, functionality, and cost based on the specific needs of your project.