How to design a LED light circuit?

Designing an LED light circuit involves understanding the basic components required and how to arrange them for optimal performance. Below is a step-by-step guide that covers the fundamentals of creating an efficient LED lighting circuit.

1. Understand the Basics of LEDs.

LEDs (Light Emitting Diodes) are semiconductors that emit light when an electric current passes through them. LEDs are more energy-efficient than traditional light bulbs but require precise voltage and current to operate correctly. A typical LED operates at 2-3V and draws 20-30mA of current.

2. Components You Will Need.

Here are the essential components for designing a simple LED circuit:

- LEDs: The core component that produces light.

- Resistors: Used to limit the current flowing through the LED, protecting it from overcurrent.

- Power Source: This can be a battery, USB power, or a regulated power supply depending on your application.

- Switch (Optional): To turn the LED on and off.

- Wires or PCB: For connecting the components.

- Breadboard (Optional): Useful for prototyping your design before making a permanent circuit.

3. Determine the Power Source and Voltage.

Choose the power source that will power your LEDs. For example:

- 5V USB power supply

- 9V battery

- 12V DC adapter

You need to match the power source voltage with the requirements of the LEDs. If the voltage is too high, you risk damaging the LED, which brings us to the importance of resistors.

4. Calculate the Resistor Value.

Resistors are critical because they control the amount of current flowing to the LED. The formula for calculating the appropriate resistor value is derived from Ohm’s Law:

R=Vs−VLEDILEDR = \frac{V_s – V_{LED}}{I_{LED}}R=ILEDVs−VLED

Where:

- VsV_sVs is the supply voltage,

- VLEDV_{LED}VLED is the forward voltage of the LED (usually between 2-3V for common LEDs),

- ILEDI_{LED}ILED is the current through the LED (typically 20mA or 0.02A).

Let’s us do an example:

If you’re using a 9V battery to power an LED with a forward voltage of 2V and 20mA current:

R=9V−2V0.02A=350ΩR = \frac{9V – 2V}{0.02A} = 350 \OmegaR=0.02A9V−2V=350Ω

So you would need a resistor of 350 ohms to prevent damage to the LED.

5. Choose the LED Configuration.

There are two main configurations to consider for multiple LEDs:

a) Series Circuit:

In a series circuit, the LEDs are connected one after the other, and the current is the same through each LED. The total forward voltage is the sum of the voltages of each LED.

Vtotal=VLED1+VLED2+VLED3V_{total} = V_{LED1} + V_{LED2} + V_{LED3}Vtotal=VLED1+VLED2+VLED3

Example: If you have three LEDs with a forward voltage of 2V each and a power source of 9V, the series circuit would look like this:

- Supply Voltage = 9V

- Total Forward Voltage = 6V (3 LEDs x 2V)

You’d need a resistor for the remaining 3V (9V – 6V = 3V) using Ohm’s Law.

b) Parallel Circuit:

In a parallel circuit, each LED gets the full voltage of the power supply, and the current is divided among the LEDs. The forward voltage remains the same, but the current required increases with each additional LED.

This setup is preferred when you want all LEDs to have consistent brightness, regardless of the number of LEDs used.

6. Assemble the Circuit.

Now that you’ve calculated the resistor values and chosen the configuration, you can proceed with assembling your circuit.

- Connect the LEDs: Wire the anode (long leg) of each LED to the positive terminal of the power supply.

- Add Resistors: In a series circuit, you can add one resistor to limit current for all LEDs. In a parallel circuit, each LED should have its own resistor.

- Complete the Circuit: Connect the cathode (short leg) of the LEDs to the negative terminal of the power supply.

- Add a Switch (Optional): Place the switch in series with the power source to control the LED on/off state.

7. Test the Circuit.

Before permanently soldering the components (if applicable), test the circuit using a breadboard to ensure the LEDs function as expected and that the resistors are correctly limiting the current.

8. Advanced Considerations.

For more complex LED circuits, like those used in LED drivers or dimming controls, you might want to explore:

- Constant Current Sources: These ensure a steady current flow, regardless of voltage fluctuations.

- Pulse Width Modulation (PWM): Useful for dimming LEDs by rapidly switching them on and off at varying intervals.

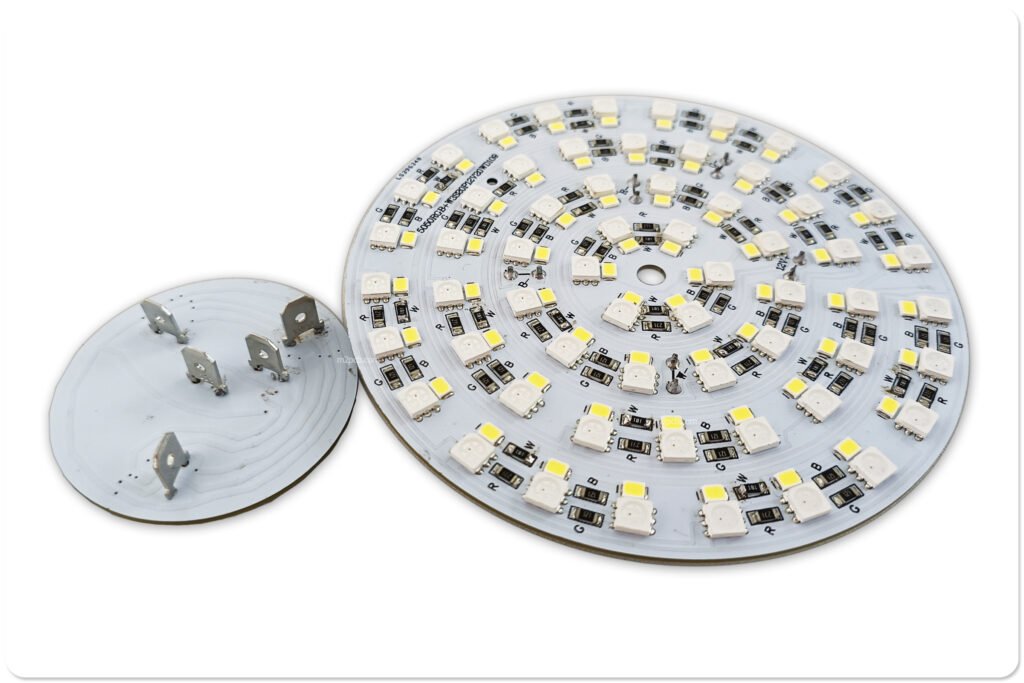

- Heat Management: High-power LEDs can generate significant heat, requiring heat sinks or metal-core PCBs for heat dissipation.

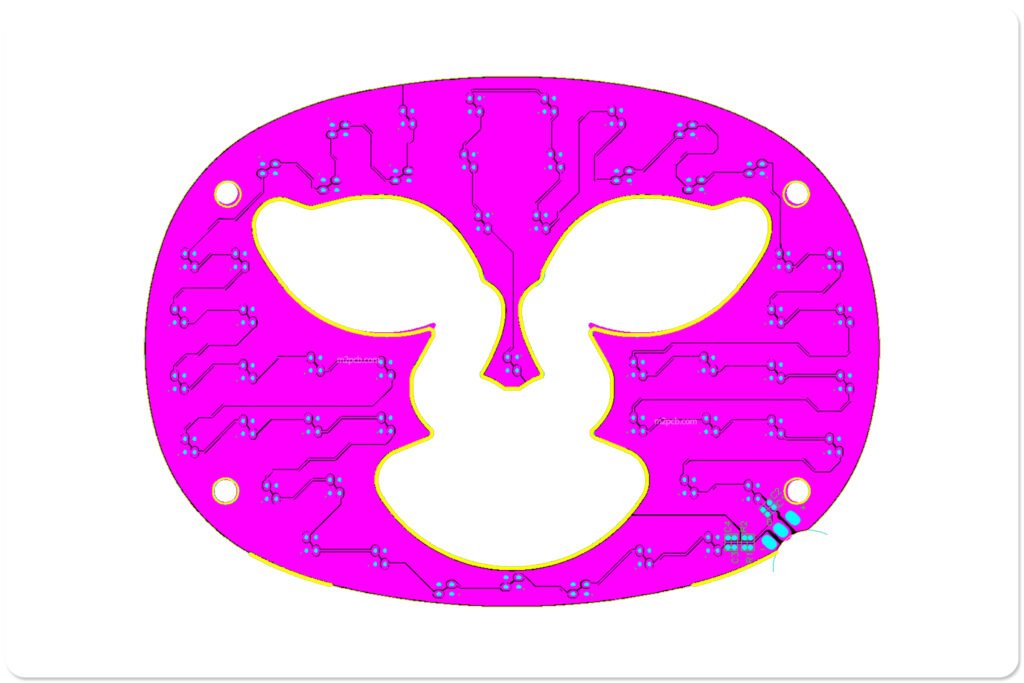

Designing an LED light circuit is straightforward if you understand the basic principles of voltage, current, and resistance. You’ll need to carefully select and calculate the resistors based on your power supply and LED specifications to avoid damaging the LEDs. After designing and testing on a breadboard, you can move to a permanent solution, such as a soldered circuit or PCB design.

If you’re planning on building more advanced or high-power LED systems, exploring constant current drivers and heat management solutions will be essential for ensuring reliability and longevity.

However, if you you need custom LED light circuits, just send message to me, we offer one-stop service, from design to assembly.